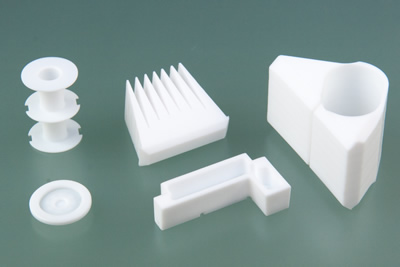

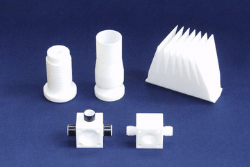

PTFE Machining

The unique properties of Teflon® (PTFE) make it very difficult to machine unless you have experience with it. Dimensional changes are often experienced if the proper techniques and material preparations are not employed. Upland Fab’s engineers have been machining Teflon for over 50 years and fully understand the necessary steps that need to be taken to produce a quality part every time. Having in-house annealing capabilities helps Upland Fab to reduce throughput time and costs by keeping the work in-house.

Teflon® Machined Parts for a Variety of Industries

Teflon® is DuPont’s trade name for polytetrafluoroethylene(PTFE)stance is required. Since Teflon® has a very low coefficient of friction, it is often used in wear applications as well as seals and gaskets. With good dimensional stability up to 500°F, Teflon® (PTFE) has found many uses in the medical industry, aerospace industry, and semi-conductor industry.

Properties of Teflon® Material

| TYPICAL PROPERTIES of Teflon® | |||||||

| ASTM or UL test | Property |

|

|

|

|||

| Unfilled | 25% Glass Filled | 25% Carbon Filled | |||||

| PHYSICAL | |||||||

| D792 |

Teflon® Density (lb/in³)(g/cm³) |

0.078 2.16 |

0.081 2.25 |

0.075 2.08 |

|||

| D570 | Water Absorption of Teflon®, 24hrs (%) |

<0.01 |

0.02 |

0.05 |

|||

| MECHANICAL | |||||||

| D638 |

Teflon® Tensile Strength (psi) |

3,900 |

2,100 |

1,900 |

|||

| D638 | Teflon® Tensile Modulus (psi) | 80,000 | - | - | |||

| D638 |

Tensile Elongation at Break (%) |

300 |

270 |

75 |

|||

| D790 | Flexural Strength of Teflon® (psi) |

No Break |

1,950 |

2,300 |

|||

| D790 |

Flexural Modulus (psi) |

72,000 |

190,000 |

160,000 |

|||

| D695 | Compressive Strength of Teflon® (psi) | 3,500 | 1,000 | 1,700 | |||

| D695 | Compressive Modulus (psi) | 70,000 | 110,000 | 87,000 | |||

| D785 | Teflon® Hardness, Shore D | D50 | D60 | D62 | |||

| D256 | IZOD Impact Notched (ft-lb/in) | 3.5 | - | - | |||

| THERMAL | |||||||

| D696 | Coefficient of Linear Thermal Expansion (x10-5 in./in./°F) |

7.5 | 6.4 | 6 | |||

| D648 | Heat Deflection Temp (°F/°C) at 264 psi |

132 / 55 | 150 / 65 | 150 / 65 | |||

| D3418 | Melting Temp (°F/°C) | 635 / 335 | 635 / 335 | 635 / 335 | |||

| - | Max Operating Temp of Teflon® (°F/°C) | 500 / 260 | 500 / 260 | 500 / 260 | |||

| C177 | Thermal Conductivity (BTU-in/ft²-hr-°F) (x10-4 cal/cm-sec-°C) |

1.7 5.86 |

3.1 10.6 |

4.5 15.5 |

|||

| UL94 | Flammability Rating of Teflon® | V-0 | V-0 | V-0 | |||

| ELECTRICAL | |||||||

| D149 | Dielectric Strength of Teflon® (V/mil) short time, 1/8" thick | 285 | - | - | |||

| D150 | Dielectric Constant at 1 MHz | 2.1 | 2.4 | - | |||

| D150 | Dissipation Factor at 1 MHz | <0.0002 | 0.05 | - | |||

| D257 | Volume Resistivity (ohm - cm) at 50% RH | 10^18 | 10^15 | 104 | |||

Deburring Teflon® (PTFE) Parts

Deburring Teflon® (PTFE) Parts

Because Teflon is so soft, burrs can be a problem when machining Teflon®. With over 50 years of plastics machining experience, Upland Fab possesses the knowledge and technologies required to produce burr-free Teflon® parts. Upland Fab uses Cryogenic Deburring to remove burrs in Teflon® parts. This process eliminates hours of labor that some shops might spend on the deburring process.

Upland Fab's Top-Flight Communication

Our approach to machining Teflon® is unique, but that’s not all that sets us apart. We offer reliable, consistent communication so that our customers always know the status of the projects. In fact, as an Upland Fabrication customer, you’ll have a single point of contact who will keep you constantly informed.

Other Materials We Work With

Are you looking for another material? We have the ability to machine many different composite machining materials take a look below at some of the other plastics we work with.

|

|

||

|

|

||

|

|

|

|

Contact Upland Fab today to learn more about the Teflon® Machining

Providing Top-flight Plastics & Composite Machining in Southern California Since 1970. Contact Upland Fab today for more information or Get a Quote. We are looking forward to hearing from you!

Contact Us Request A Quote