PEEK Machining

Often times due to the high performance applications of PEEK, parts are designed with precise tolerances and finishes. Polyether ether ketone (PEEK) is a colorless organic polymer thermoplastic used in engineering applications. This is very common in fluid applications such as seals and manifolds. Holding these tolerances and finishes requires a good knowledge of the machining characteristics of PEEK. Upland Fab has been machining all grades of PEEK for decades, giving us that experience to produce a quality part the first time. When machining the filled grades of PEEK , it is critical to properly manage the stresses in material, our engineers employ precisely controlled processes to control these stresses.

CNC Machining PEEK

For PEEK polyetheretherketone applications requiring strength and dimensional stability for continuous use up to 500°F, PEEK plastic is the perfect choice. An additional application of PEEK is when good chemical resistance is required, often PEEK plastic is used in place of fluoropolymers when used at elevated temperatures. These properties are suited perfectly for use in the medical industry, aerospace industry, semi-conductor, and oil and gas industries. PEEK materials can be purchased in sheet, rod, and tube formats with unfilled, 30% glass-fiber and 30% carbon fiber reinforced and bearing grade options.

Properties of PEEK Material

| TYPICAL PROPERTIES of EXTRUDED PEEK (compression molded and injection molded versions also available) updated 19 May 2008 |

||||||

| ASTM or UL test | Property | Unfilled | 30% Glass Fibers | 30% Carbon Fibers | Bearing Grade | PEEK HT ™ |

| PHYSICAL PROPERTIES OF EXTRUDED PEEK | ||||||

| D792 | Density (lb/in³) (g/cm³) |

0.047 1.31 |

0.056 1.54 |

0.051 1.41 |

0.052 1.44 |

0.047 1.32 |

| D570 | Water Absorption, 24 hrs (%) | 0.1 | 0.1 | 0.06 | 0.05 | - |

| MECHANICAL PROPERTIES OF EXTRUDED PEEK | ||||||

| D638 | Tensile Strength (psi) | 16,000 | 15,000 | 19,000 | 11,000 | 11,000 |

| D638 | Tensile Modulus (psi) | 500,000 | 900,000 | 1,100,000 | 850,000 | 500,000 |

| D638 | Tensile Elongation at Break (%) | 20 | 3 | 5 | 2 | 20 |

| D790 | Flexural Strength of Peek (psi) | 25,000 | 28,000 | 25,750 | 27,500 | 27,000 |

| D790 | Flexural Modulus (psi) | 600,000 | 1,000,000 | 1,250,000 | 1,100,000 | 600,000 |

| D695 | Compressive Strength of Peek (psi) | 20,000 | 26,000 | 29,000 | 26,700 | 20,000 |

| D695 | Compressive Modulus of Peek (psi) | 500,000 | 1,000,000 | - | 1,000,000 | - |

| D785 | Hardness, Rockwell | M100 (R126) | M103 | M102 | M85 | R108 |

| D256 | IZOD Impact Notched (ft-lb/in) | 1 | 1.4 | 1 | 0.7 | - |

| THERMAL PROPERTIES OF EXTRUDED PEEK | ||||||

| D696 | Coefficient of Linear Thermal Expansion of Peek (x 10-5 in./in./°F) |

2.6 | 1.2 | 1 | 1.7 | - |

| D648 | Heat Deflection Temp (°F / °C) at 264 psi |

320 / 160 | 600 / 315 | 550 / 288 | 383 / 195 | 329/165 |

| D3418 | Melting Temp of Peek (°F / °C) | 644 / 340 | 644 / 340 | 644 / 340 | - | 705/374 |

| - | Max Operating Temp of Peek (°F / °C) | 480 / 249 | 480 / 249 | 500 / 260 | 482 / 250 | - / - |

| C177 | Thermal Conductivity of Peek (BTU-in/ft²-hr-°F) (x 10-4 cal/cm-sec-°C) |

1.75 6.03 |

2.98 10.3 |

6.4 22 |

1.7 5.9 |

- - |

| UL94 | Flammability Rating of Peek | V-0 | V-0 | V-0 | V-0 | V-0 |

| ELECTRICAL PROPERTIES OF EXTRUDED PEEK | ||||||

| D149 | Dielectric Strength (V/mil) short time, 1/8" thick | 480 | 500 | 32 | - | - |

| D150 | Dielectric Constant at 1 MHz | 3.3 | 3.7 | - | - | - |

| D150 | Dissipation Factor at 1 MHz | 0.003 | - | - | - | 0.003 |

| D257 | Volume Resistivity (ohm-cm) at 50% RH of Peek | 4.9 x 1016 | 5 x 1016 | 105 | 103 | 1016 |

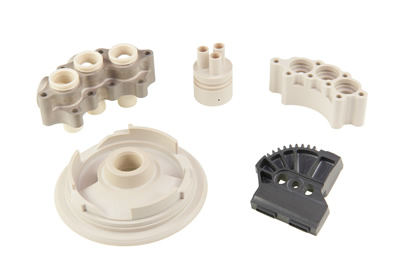

PEEK Parts and CNC Technologies

Upland Fab employs the use of multi-axis machining when working with PEEK. This application of technology is critical to ensuring the parts are machined correctly the first time with minimal handling and fixturing. Often times even the most complex parts are completed in a single operation.

Upland Fab machines complex PEEK components directly from customer-supplied CAD models. Our DPD/MBD processes (Digital Product Definition, also referred to as Model-Based Definition) allow us to reduce manufacturing errors, which in turn allows us to produce PEEK parts at a very low cost. Have questions about our DPD process? Give us a call today at 909-986-6565 to discuss your next PEEK project.

Stay Up-To-Date On Your Project With Top-Flight Communication

At Upland Fab, communication is a top priority. By providing reliable, consistent communication to our customers, we are able to offer something that our competitors don’t: peace of mind. As an Upland Fab customer, you will work with a single point of contact who will keep you up-to-date on the progress of your project – every step of the way. Send us your project requirements today!

Other Materials We Work With

Are you looking for another material? We have the ability to machine many different materials take a look below at some of the other plastics we work with.

|

|

||

|

|

||

|

|

|

|

Contact Upland Fab today to learn more about PEEK Polyetheretherketone Machining

Upland Fab has been providing top-flight plastics & composite machining in Southern California Since 1970. Contact Upland Fab today for more information or get a quote. We look forward to hearing from you!